Sustainable Packaging Materials: A Comprehensive Overview

Read More

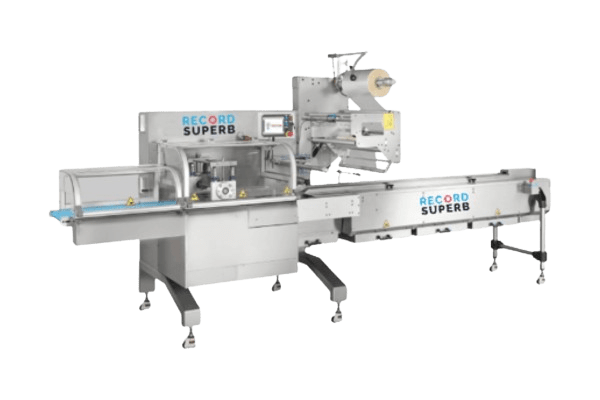

When exploring packaging solutions, it’s easy to assume all flow wrappers are the same. In reality, the technology comes in several key variations, each designed to excel at different tasks. Choosing the right type of flow wrapper for your product is crucial for maximising efficiency, ensuring product integrity, and getting the best return on your investment. At Record Packaging, we work with businesses every day to identify the perfect machine for their specific needs.

This is the most common type of flow wrapper, characterised by a rotating jaw system that creates the cross-seal.

Also known as Long Dwell or Reciprocating Jaw flow wrappers, these machines use a different sealing mechanism.

While not a separate category, these machines represent the pinnacle of flow wrapping technology, often combining the best of both Rotary and Box Motion systems with advanced automation.

“The choice between a Rotary, Box Motion, or a full-servo machine is about finding the right balance of speed, seal quality, and product handling. There is no one-size-fits-all solution. Our job is to help our customers navigate these options to find the perfect piece of equipment that will serve their business now and into the future.”

— Robert Murphy, Sales Director, Record Packaging Systems